General guidelines

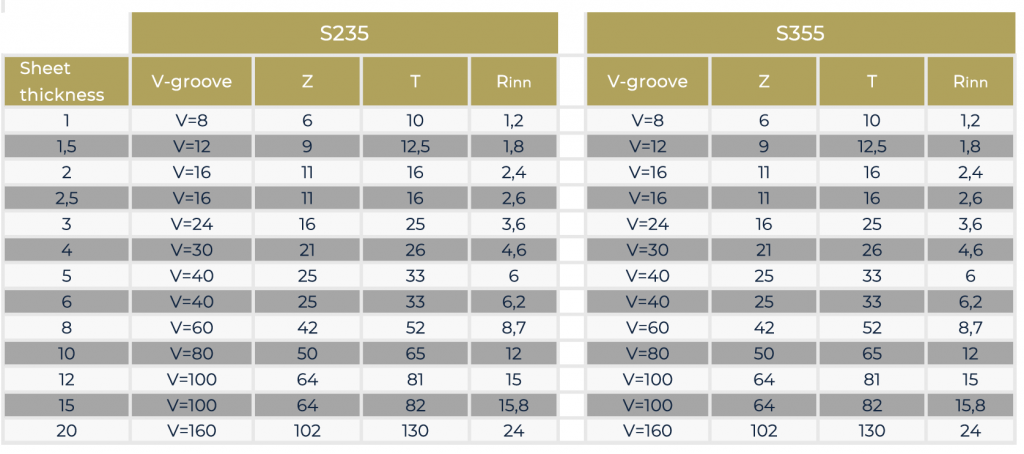

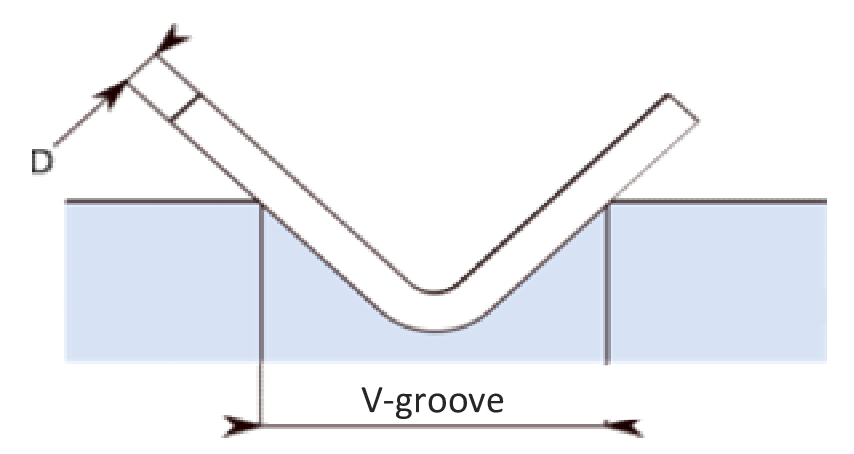

Guideline for V-groove (nominal)

V = 8 x D

Guideline for V-groove (minimal)

V = 6 x D

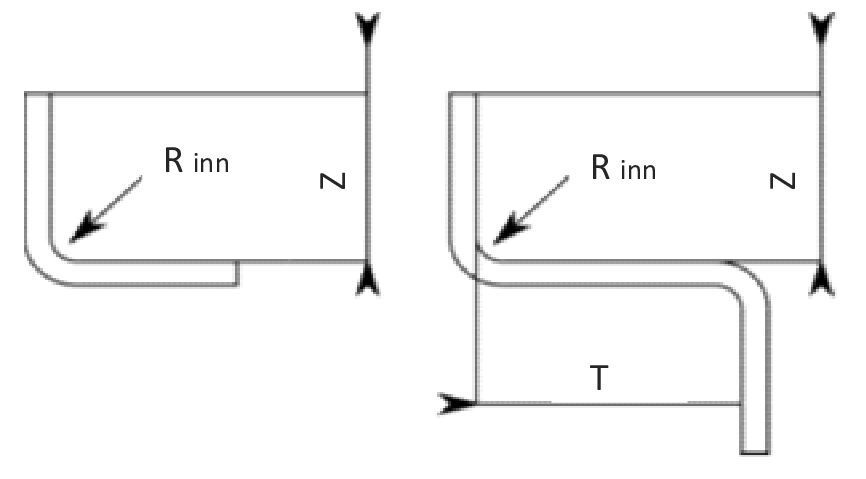

The minimum bend length then is:

Z = V / 2

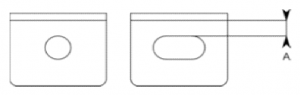

Minimum distance from holes:

A = V / 2 – 1

Minimum distance from slotted hole

A = V / 2 + 1

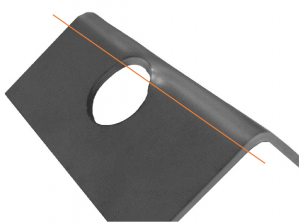

It could be that the design does not allow to keep this distance. If you would choose to place the whole closer to the bending line, the metal will protrude there where the edges did not lay on the die. This is best explained by the following picture, where in the orange line simulates the imprint of the V-groove of the die:

In order to prevent this a relief could be added so that edge of the whole does not fold along with the rest of the sheet, like shown below:

L = min length (diameter) of the hole

W = 0,8 x D (minimum)

Add a comment